If you are looking for a complete software solution, you have come to the right place!

Enfotek MDS is a Management System for High-Quality Knitted and Woven Fabric Production.

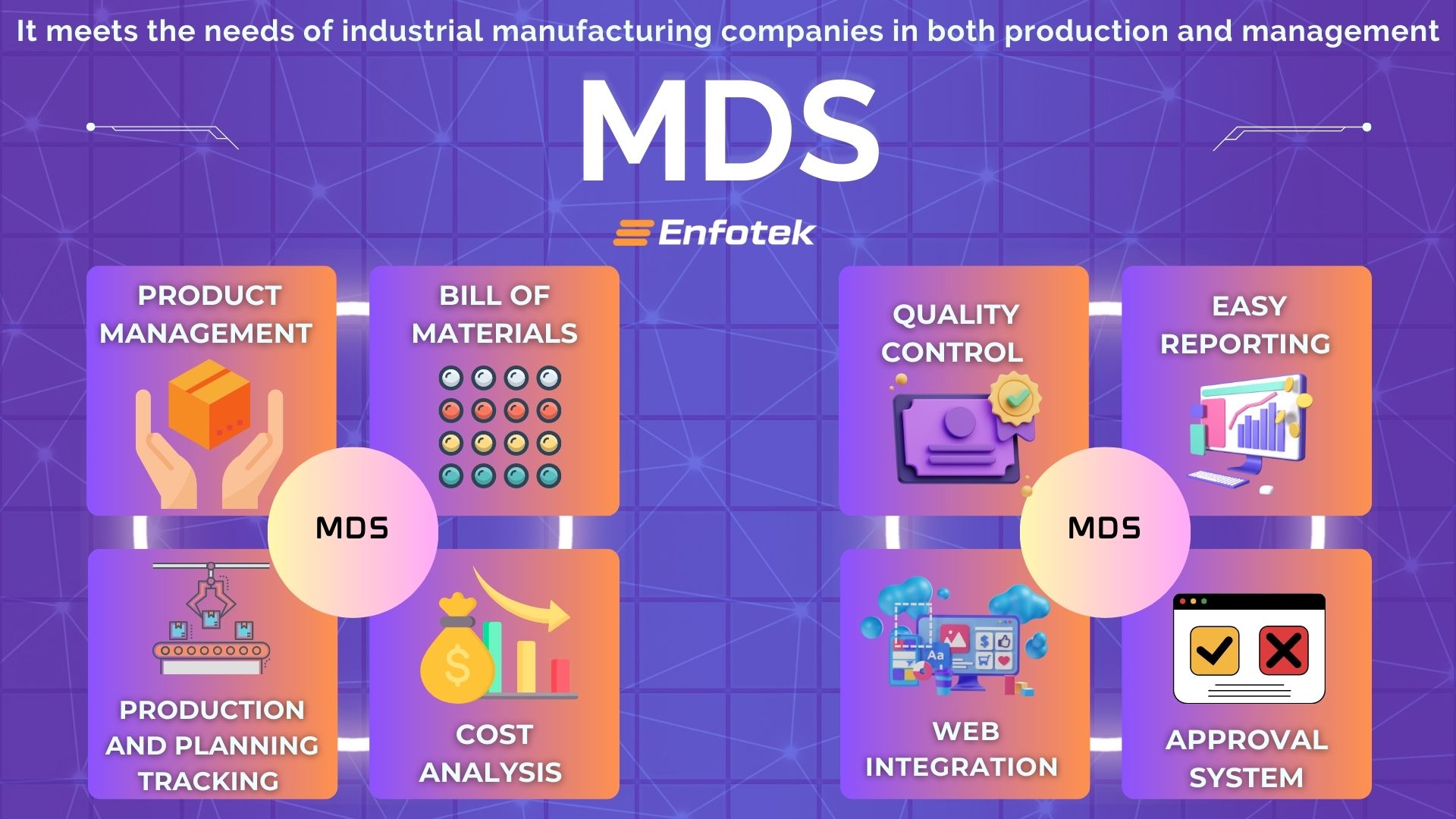

Enfotek MDS is a leading management system for knitted and woven fabric production. This innovative and user-friendly software provides textile manufacturers with quality, efficiency, and competitive advantage. MDS offers an integrated solution for managing the entire production process from start to finish.

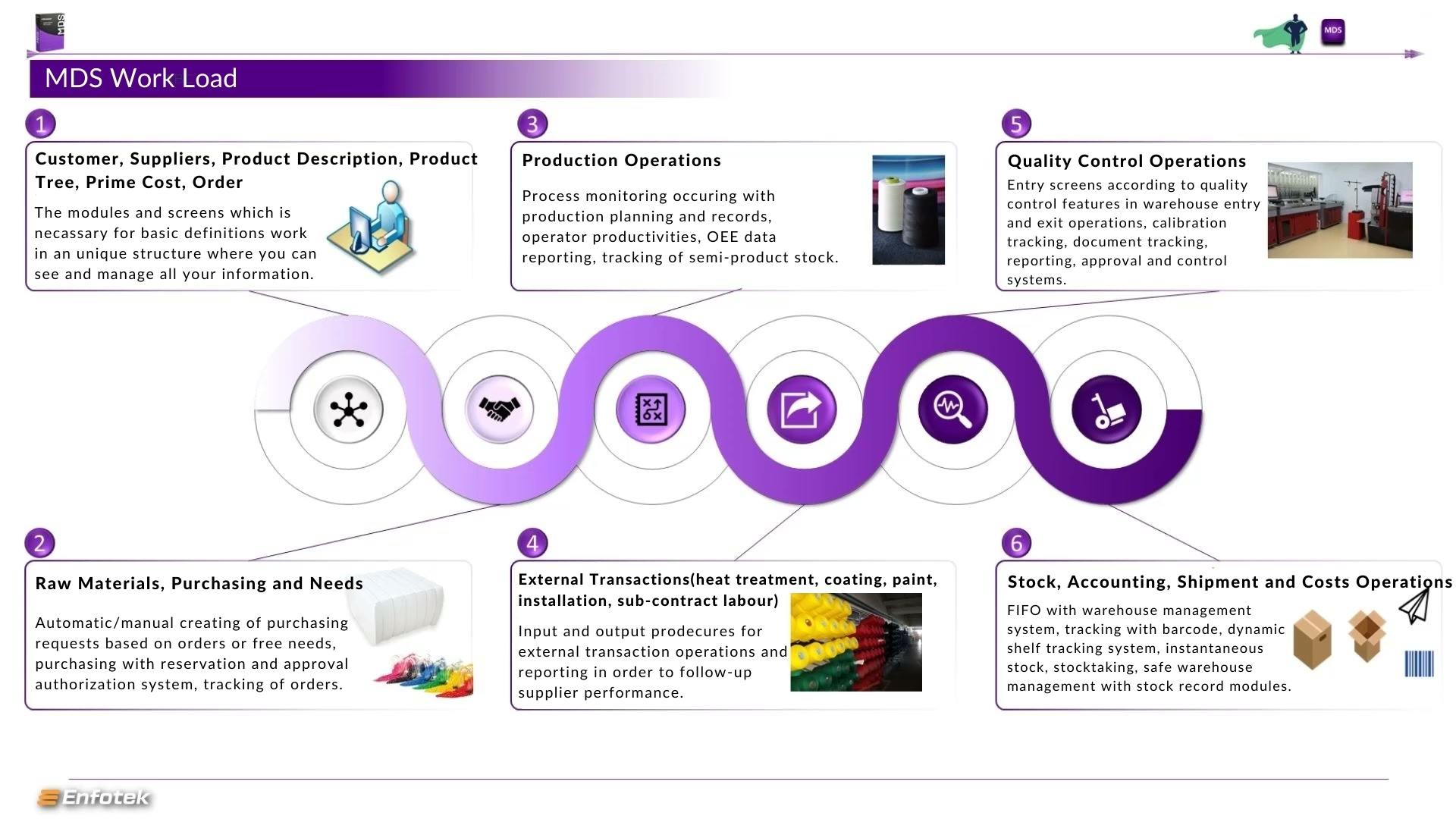

It combines all stages such as order management, creating technical drawings, raw material procurement, production planning, operation of weaving or knitting machines, quality control, and inventory tracking under one system. This allows manufacturers to better manage processes, avoid errors, and increase their productivity.

The user-friendly interface of Enfotek MDS is designed in a way that can be easily understood by users at all levels. Users can track the entire production process, analyze data, and make interventions when necessary through a single platform. Additionally, the system provides real-time information to enable fast and accurate decision-making.

One of the main advantages of Enfotek MDS is its ability to increase operational efficiency and reduce costs. It achieves high efficiency by effectively utilizing factory resources. Furthermore, it ensures the production of high-quality products while minimizing waste, making it compatible with environmentally friendly working principles.

Enfotek MDS also enhances supply chain management. It ensures the tracking and coordination of important processes such as supplier management, logistics management, and material management. This enables better collaboration with suppliers and ensures timely and accurate material procurement. For high-quality woven and knitted fabric production,

Enfotek MDS is a comprehensive and effective solution. Textile manufacturers can gain a competitive advantage, increase customer satisfaction, and become industry leaders with this powerful management system. Contact us or visit our website to learn more about Enfotek MDS and to view our product brochure. Choose Enfotek MDS for quality and efficient woven and knitted fabric production!