If you are looking for a complete software solution, you are in the right place!

Enfotek offers appropriate software solutions for all size of business that produces for export or domestic market.

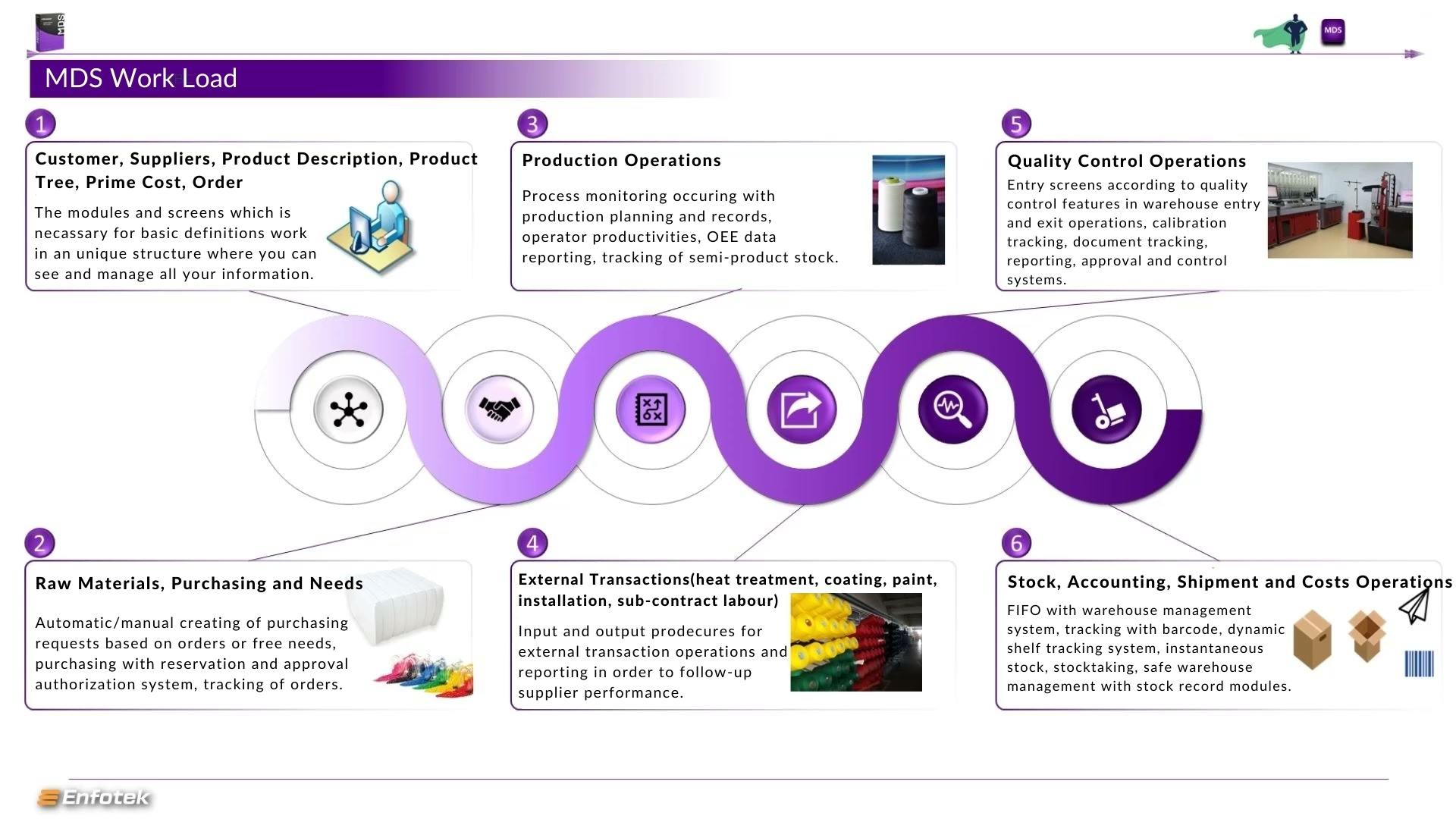

MDS is designed to meet all kinds of needs for industrial manufacturing companies that require precision in both production and management. MDS is an alive system that adapts to you and compromises your needs with best practices.

With Enfotek MDS, reduce your costs and increase efficiency, work more informed and in control.

Enfotek MDS ERP offers a customized solution for dyeing processes, simplifying all your production processes and enhancing efficiency. With years of experience in the dyeing sector, Enfotek provides an ERP system that exactly meets your needs.

The adaptation of Enfotek MDS ERP for dyeing operations facilitates data sharing across all departments of your business by promoting integration. This system allows you to monitor every step in the dyeing process, incorporating crucial functions ranging from raw material management and production planning to stock control and cost analysis. Raw material management plays a critical role in the dyeing process. Enfotek MDS ERP enables you to easily track your raw material purchases and view stock status in real-time. It automatically monitors stock levels, ensuring timely reordering to maintain production continuity.

Production planning is key to success. Enfotek MDS ERP automates this process, allowing your business to optimally utilize resources. By efficiently using production capacity, it helps you meet customer demands and shorten delivery times. For dyeing operations, stock control is a significant way to reduce costs.

Enfotek MDS ERP continuously monitors stock levels, preventing unnecessary stock accumulation and minimizing costs. It also facilitates inventory management by providing detailed reports on stock movements, ensuring resources are used accurately. Moreover, Enfotek MDS ERP simplifies cost analysis. By tracking every step of the production process, it helps you keep costs under control. This allows you to identify unnecessary expenses and increase profitability.

Furthermore, thanks to Enfotek MDS ERP's user-friendly interface, you can easily use the system and quickly analyze your data. This customizable system can scale according to the size and needs of your business.

Enfotek MDS ERP represents a reliable and innovative solution from Enfotek, with extensive experience in the dyeing field. Switch to Enfotek MDS ERP to increase your business's efficiency, reduce costs, and gain a competitive edge! Contact us for more information and to learn about the advantages of Enfotek MDS. Collaborate with Enfotek to simplify your dyeing process and take a significant step towards success.